- Plastic Molding

- Design and Manufacturing Metal Dies

- Measurement and Testing

- Surface Treatment / Micro Blasting

Services

- Inquries about our services

- Facility Information

Plastic Molding

We own 15t-100t injection molding machines, to handle small quantity orders to mass production.

First class molding professional

1 certified professionals present

Second class molding professional

7 certified professionals present

We will work towards a solution for all customers. Please feel free to consult with us.

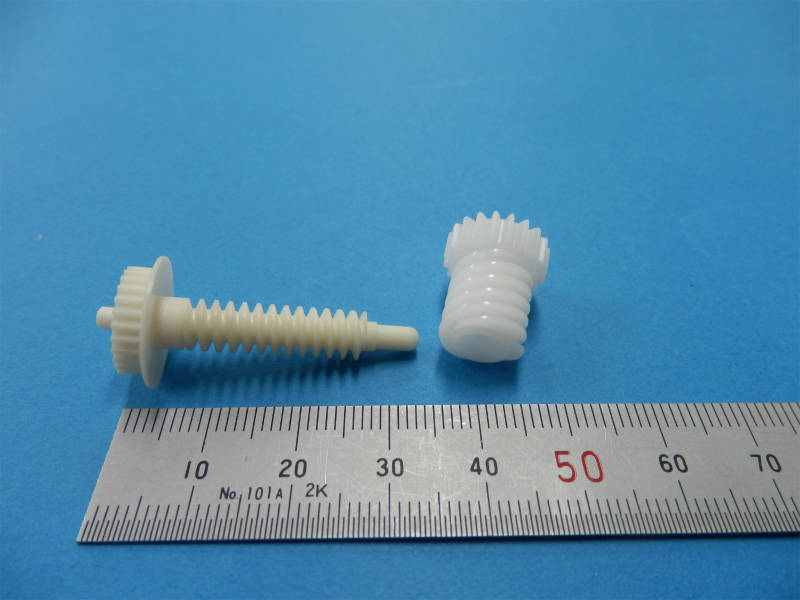

High Precision Molding Products

Parts such as gears and shafts manufactured by injection molding are lighter and cost-efficient alternatives for traditional metal products.

| Form | Gears, worm drives |

| Precision | Concentricity Less than 0.02 |

| Circularity Less than 0.02 | |

| Helical gear meshing JGMA Level 3 to 5 | |

| Spur gear meshing JGMA Level 0 to 5 | |

| Size | Gear shape φ 3 to 40mm |

Concentricity, Worm-Removal Structure Technology in Dies

| Uses | Home electronics, cars |

| Characteristics | Concentricity, Worm-Removal Structure Technology in Dies |

Thin-wall Molding Products

| Size | Outer diameter φ 12 to 20mm Thickness Less than 0.015 |

| Characteristics | Thin-wall molding, concentricity |

Molding of Engineered Plastics Such as PPS and LCP

We do injection molding of engineered plastics such as PPS, LCP (liquid crystal polymer) and elastomer.

Materials

Super Engineering resin

・PPS

・LCP

・PEEK

Engineering resin

・PA (nylon / polyamide)

・PC (polycarbonate)

・POM (polyacetal)

・PBT (polybutylene terepthalate)

・PPE (polyphenylene ether)

General purpose materials

・ABS resin

・PP (polypropylene)

・PE (polyethylene)

・PS (polystyrene)

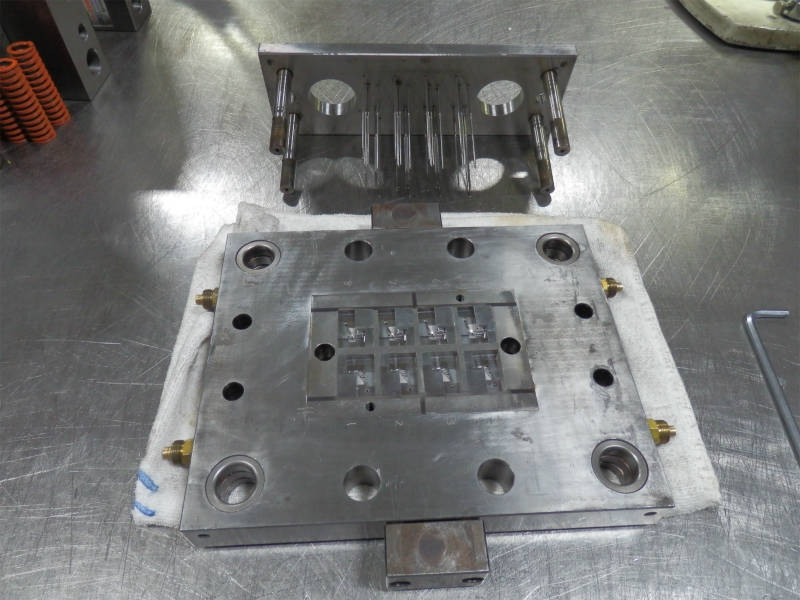

Design and Manufacturing Metal Dies

Manufacture and assembly of precision dies

We also produce metal precision dies. Integrated production is possible. We will accommodate your needs from prototypes to mass production.

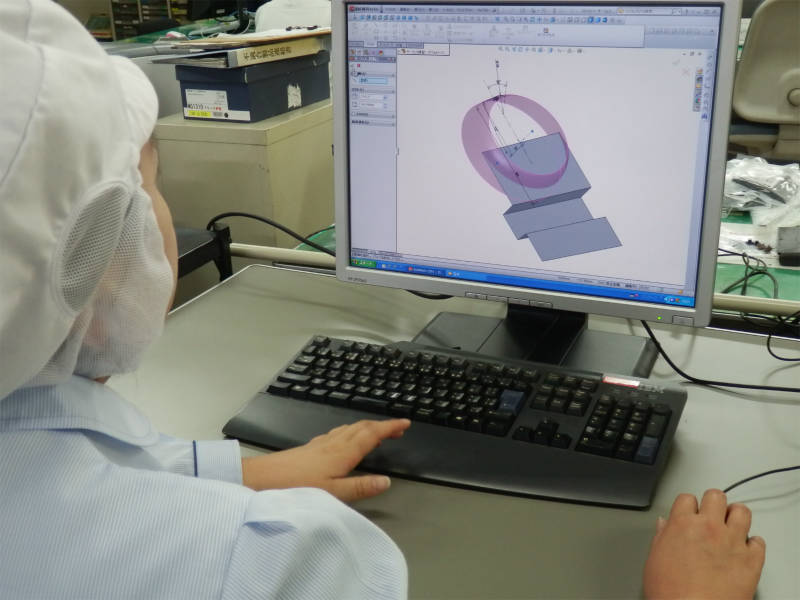

Die design and molding

In addition to injection molding we also offer designing and developing of special structure dies and hot runners.

Die maintenance

We carry out maintenance within our own company. In any cases of trouble, we will resolve it promptly.

Measurement and Testing

We have various measurements to stabilize the quality of our products. Testing criterias will be set accordingly to necessary structures and elements.

1 Level 2 QC

11 Level 3 QCs present

Extensive measuring equipment

We have a dedicated inspection room where we conduct various and thorough inspections using instruments such as image measuring machines, CNC three-dimensional measuring machines, roundness measuring machines, gear meshing test machines, etc.

We only deliver products that have passed the inspection and meets environmental standards.

We also accept inspection and measurement orders.

Surface Treatment / Micro Blasting

We implemented a micro-blasting machine by IEPCO for washing machine screws, improving mold releasabilities, maintenance of molds, etc, to improve productivity.